Modelling and simulation of Fuel Cell Electric Vehicle (FCEV)

Because of the limitation on the distance covered in one charging cycle, BEV poses still a practical challenge for long distance travel. Fuel cell technology comes in picture at this juncture. With a chemical reaction between Hydrogen & Oxygen, the current is generated and output is nothing but water without any emission. This current is used to power the vehicle. Fuel Cell and Hydrogen Storage tank are the main components of the Fuel Cell Technology. PEM (Proton- Exchange Membrane also referred as Polymer Electrolyte Membrane) & SOFC (Solid Oxide Fuel Cell) are the major types of electric current generation methods in the Fuel Cell System. Implementation of Fuel Cell systems in commercial vehicles and stationary power generation will be the upcoming technology trends.

Fuel Cell Electric Vehicle Modeling and Simulation Projects carried at our team.

- Estimation of membrane dry out fraction during charging and discharging.

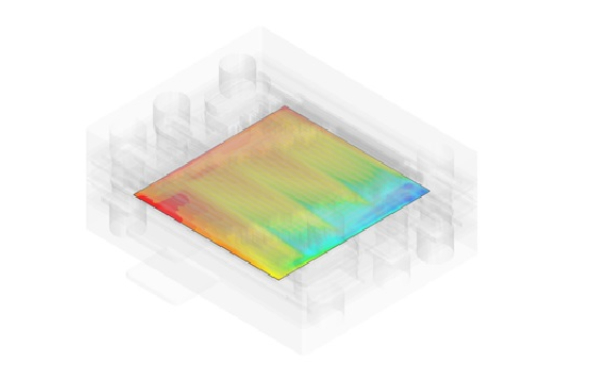

- Thermal performance of the fuel cell & Evaluation of external cooling requirements.

- 3D CHT Simulation – Evaluation of pressure rise inside the tank for variation in the ambient temperature and predicting the temperature distribution across the cylinder thickness.

- Hydrogen Filling and Emptying Simulation – Identifying the time required for filling and emptying for hydrogen tank for required operating condition.

- Hydrogen diffusion after leak Simulation- To identify the fraction of leak hydrogen inside the car cabin.

- Structural simulation of Hydrogen Tank- Predicting the stresses induced and deformation for the mapped internal pressure. Identification of crack propagation for the operating tank pressure.

- Cyclic / Random vibration of Hydrogen Tank – Predicting system behavior under cyclic / random vibration loading.

- Thermal Management of Fuel Cell electric vehicle.