Internal Combustion Engine (ICE) Powertrain

The first commercial IC engine in the market was in 1872. From that point till today and probably for a few more decades to come, IC engine is the most reliable technology for the mobility & power generations and will remain so.

Designers need to consider aspects of thermodynamics, structural mechanics NVH, fluid behaviour, kinematics and what not while developing an ICE powertrain. This makes it one of the most complicated systems to be engineered. In the recent years, fuel efficiency, emissions, light weight requirements have added further challenges.

At ESPL, we are supporting our customers in the Internal Combustion Engine Powertrain system simulations practically from the day one. Over the years, we have developed very good expertise in multi-physics engineering solutions while simulating almost all Physics associated with ICE Powertrain.

Systems Know- how

- Engine

- Valvetrain

- Cranktrain

- Exhaust & Turbocharger

- Intake & EGR

Multi- Physics Expertise

- Heat Transfer

- Fluid Dynamics

- Structural Mechanics

- Thermo- Structural

- Structural Dynamics & NVH

Technology Implemented

- FEA/ FEM

- CFD

- 1D System Simulation

- Multi- Disciplinary Optimization

Achievements in the Powertrain Domain

- 4 Powertrain OEMs as ESPL’s long term customers

- 18+ Engine programs (2/3/4/6 Inline, V8/V12)

- Managed more than 3 large powertrain development Programs in parallel for the customer

- Developed tools, methodologies, and scripts for better efficiency in improving quality, project time and overall cost over the years.

- Achieved time savings in model building by over 24%

- Achieved time saving in engine assembly simulation by over 50%

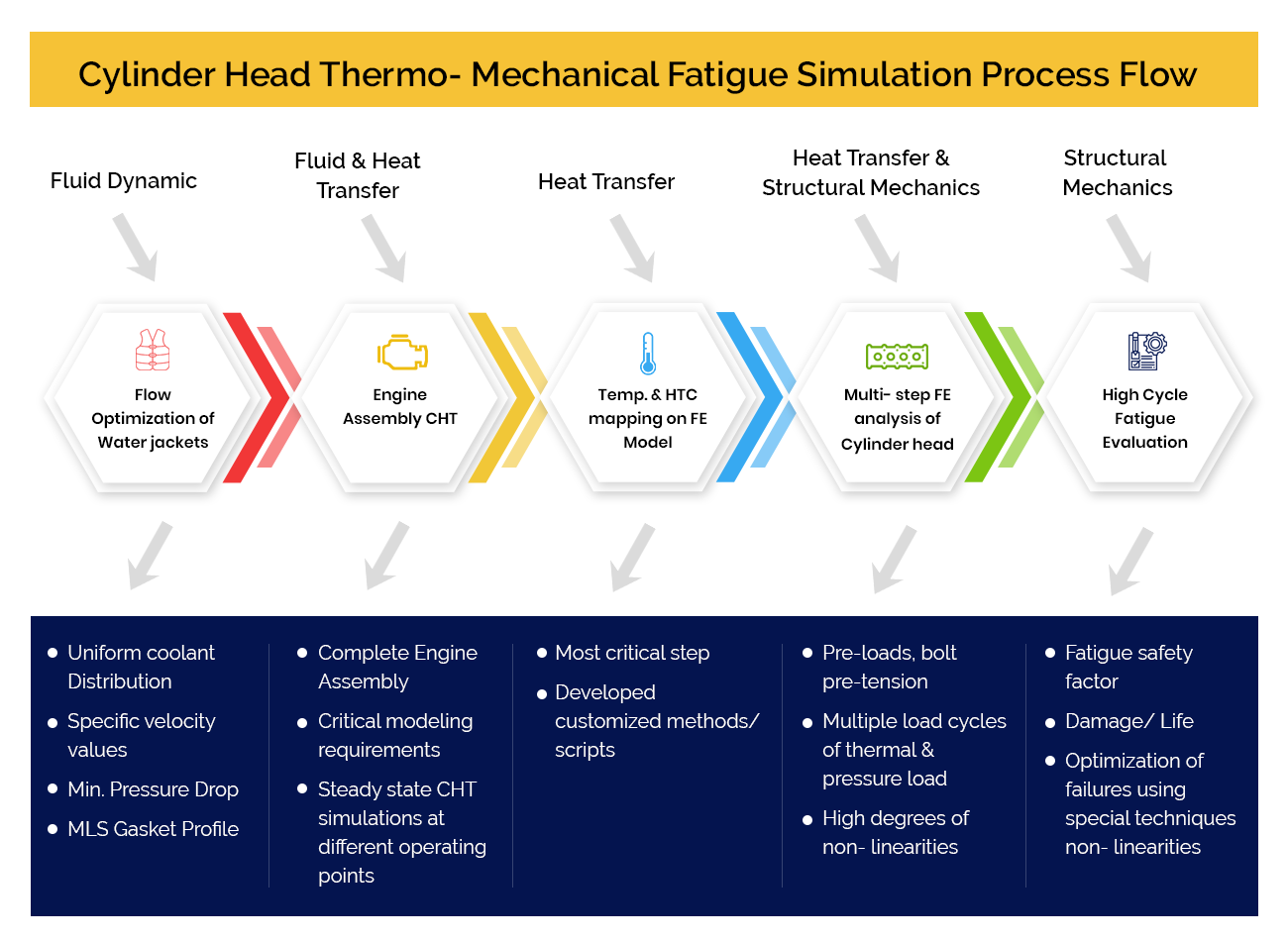

How MLS (Multi- Layer Steel) gasket can be designed out of CFD simulations? Our Powertrain CFD expert can explain. Get in touch with our expert.