1D System Simulation enables rapid modeling and analysis of complex systems with simplified representations. It provides insights into system behavior, performance, and multi-physics interdependencies early in the design phase, particularly in transient cycle simulations.

The applications of 1D Systems simulations include automotive, aerospace, and industrial domains for system-level optimization.

1D system simulation offers several advantages. One of the most significant is that it reduces development time and cost and helps expedite innovations in engineering solutions.

ESPL: Global GT-SUITE Service Providers listed by Gamma Technologies Inc.

GT-Suite, developed by Gamma Technologies, is one of the most reliable 1D System simulation tools. The company has identified premium consulting firms experienced in using GT-SUITE and established long-lasting relationships with them. At ESPL, we are pleased to inform you that we are one of the listed Engineering consultancy firms using GT-Suite. www.gtisoft.com

1D System Offerings

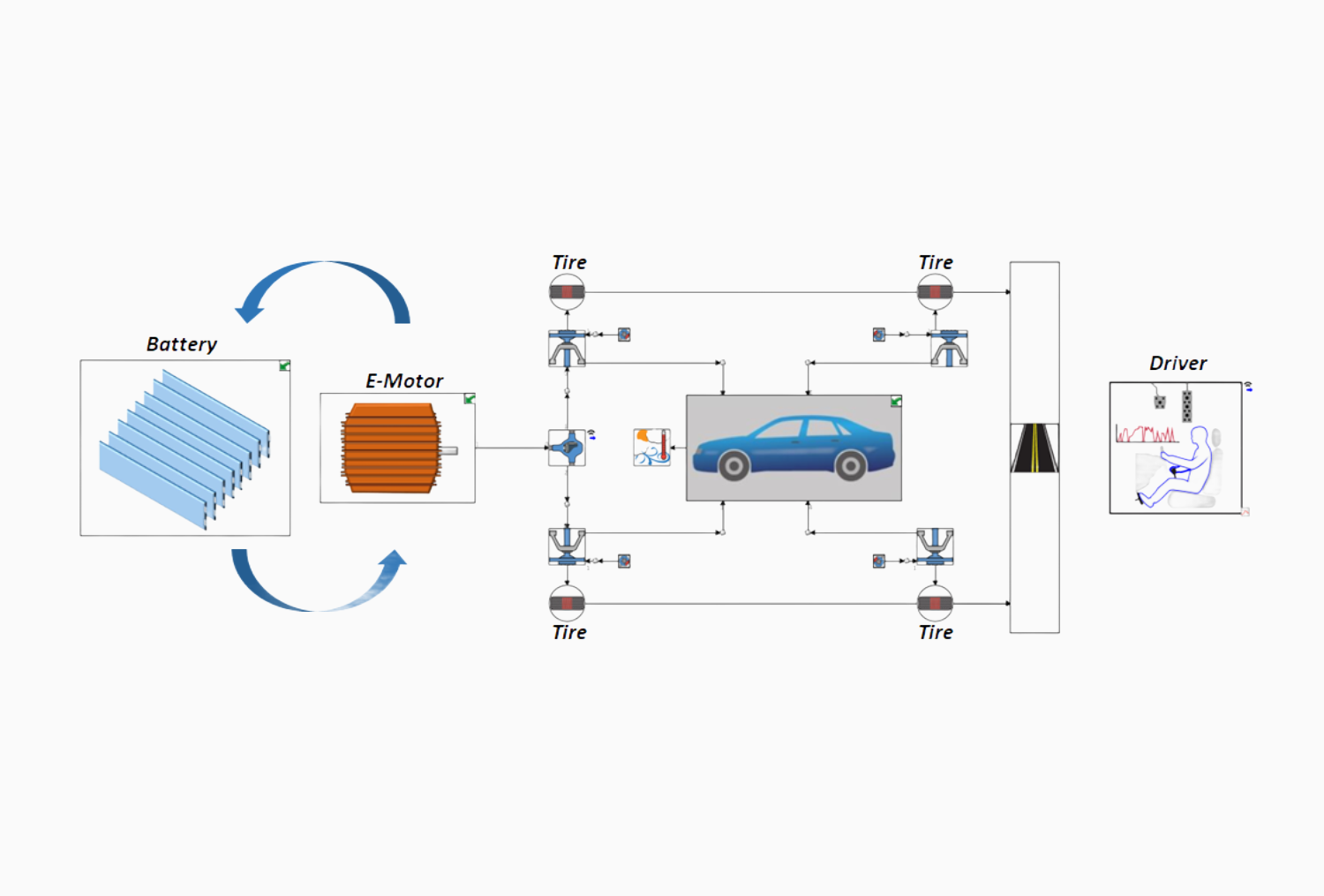

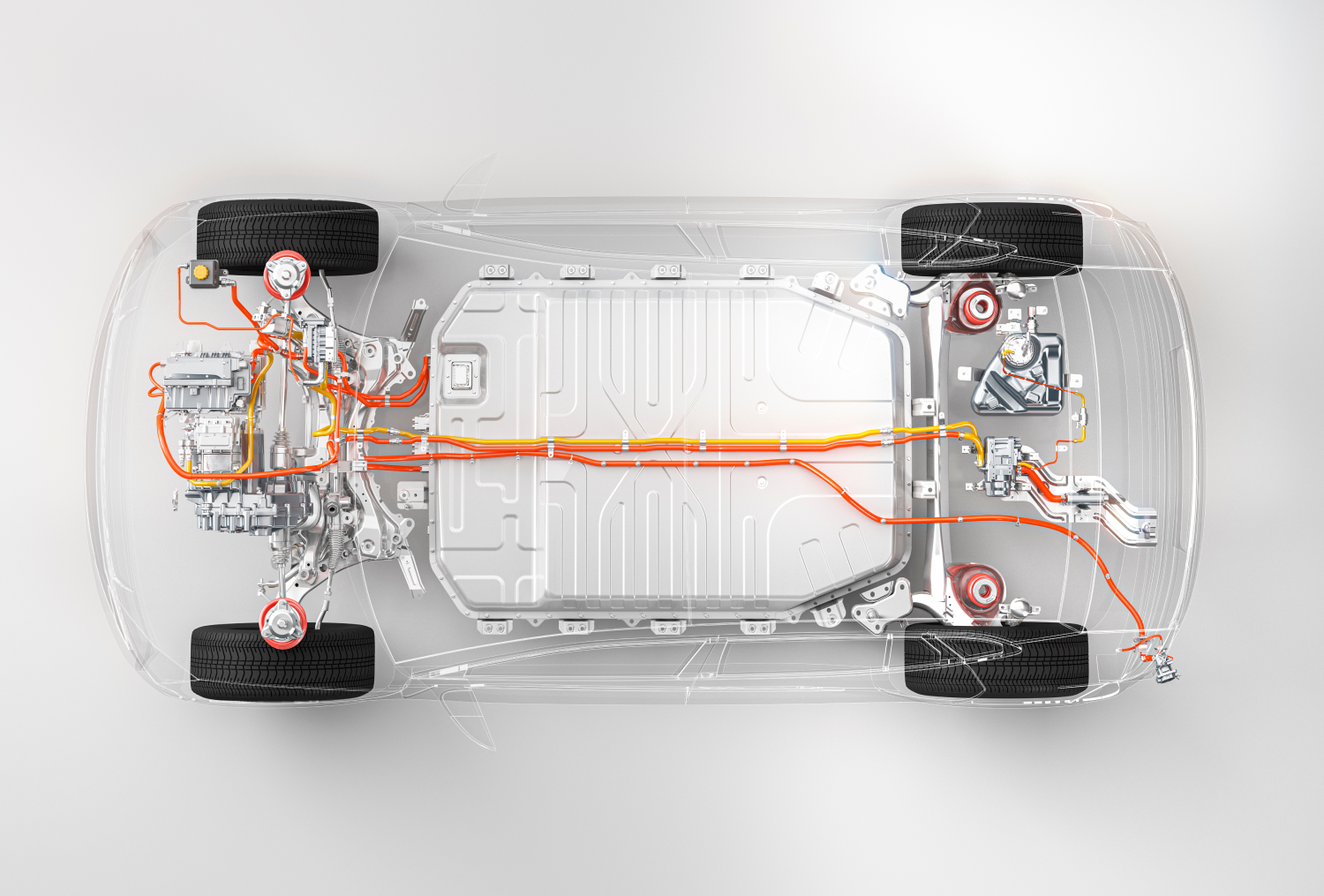

Vehicle Integration

- Vehicle Thermal Management

- Integration of system level models

- Coolant Circuits performance/ optimization

- Air Intake System

- Underhood

- Driveline Performance

- Range Prediction

- Drive Cycle Simulation

- Test Co-relation

- 1D-3D Coupling

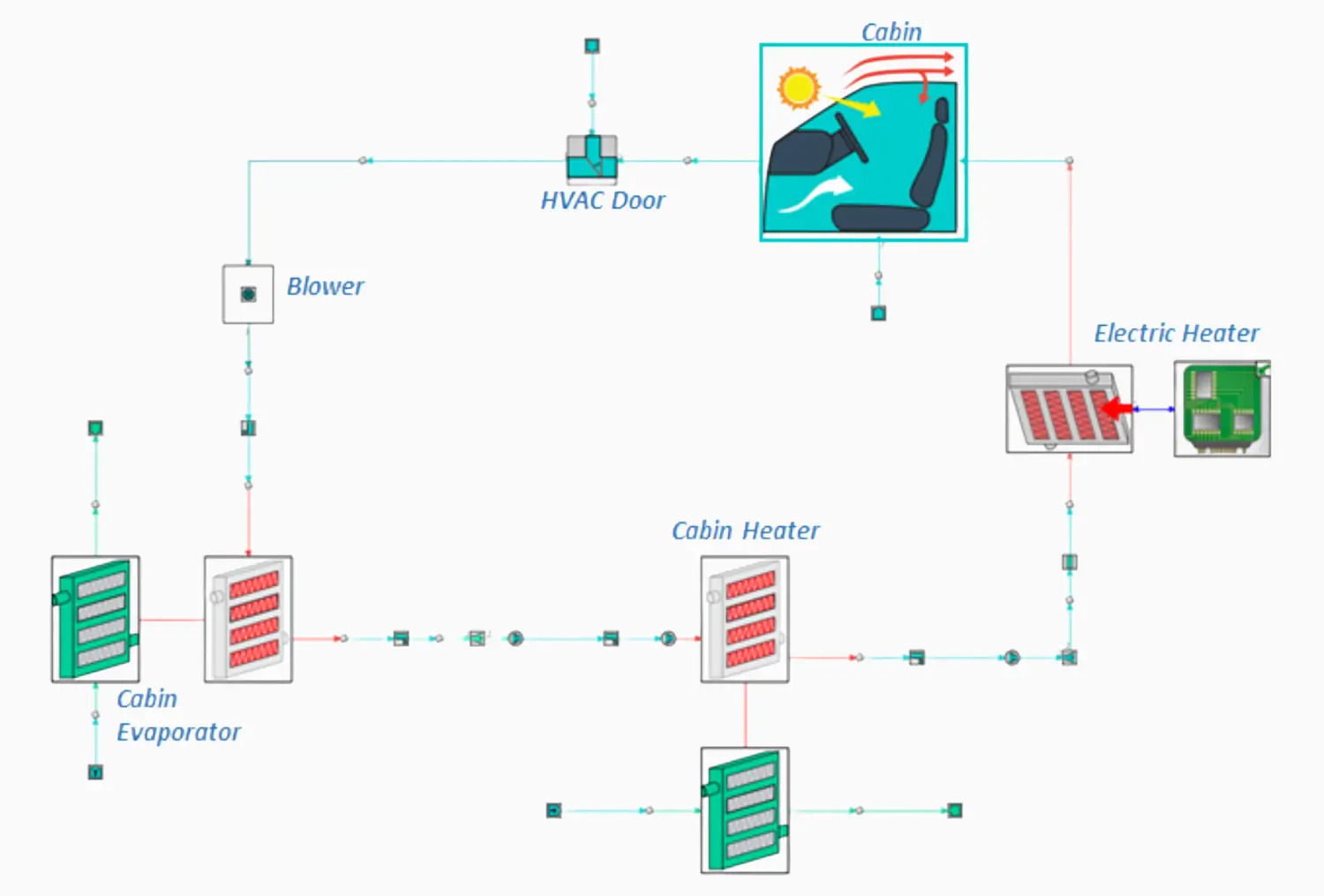

Cabin HVAC

- Passenger Comfort

- Cabin Warm up

- Cabin cool down

- Duct Optimization

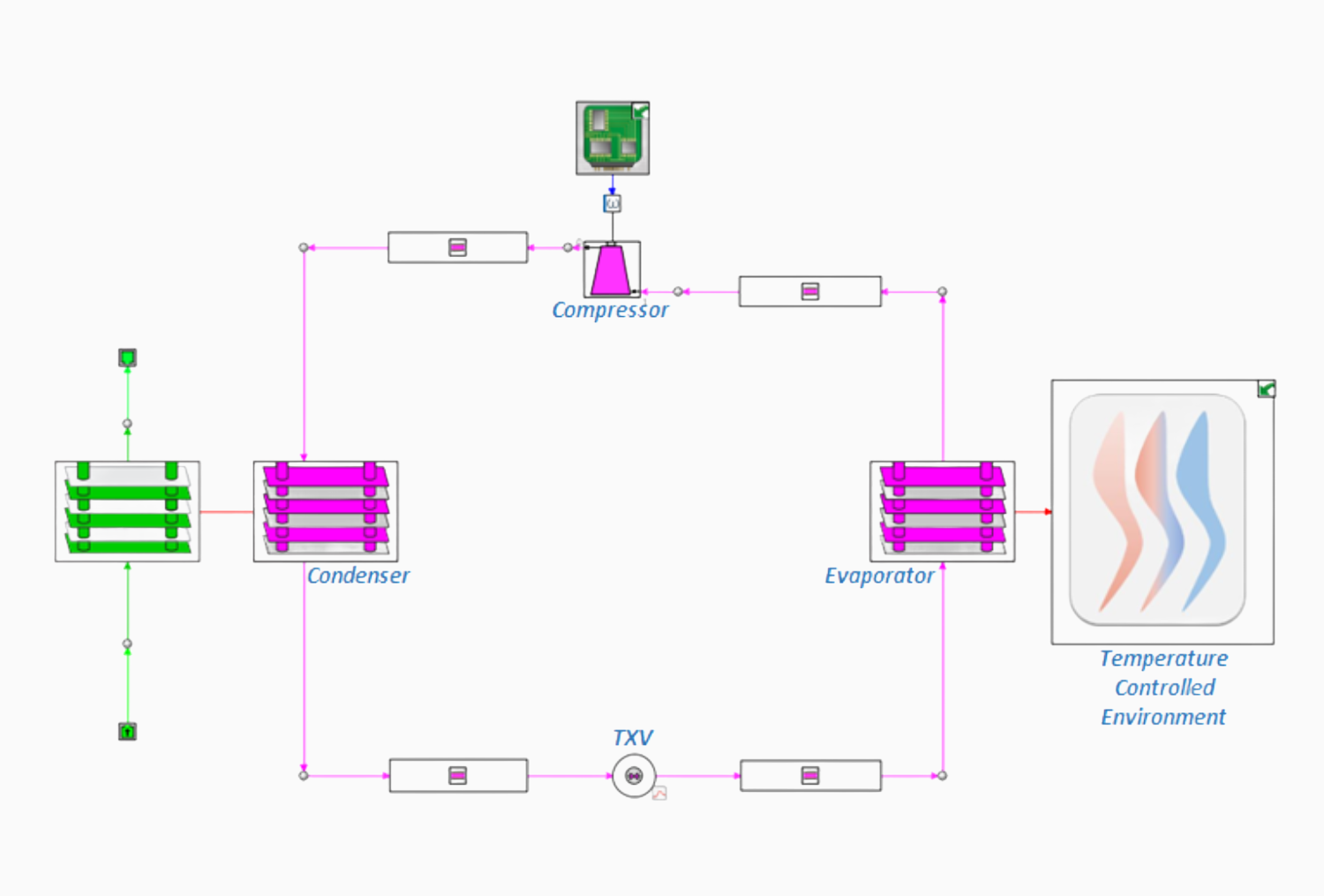

Refrigeration System

- Sizing simulations

- Heat Exchanger (Condenser, Evaporator)

- Transient cycle

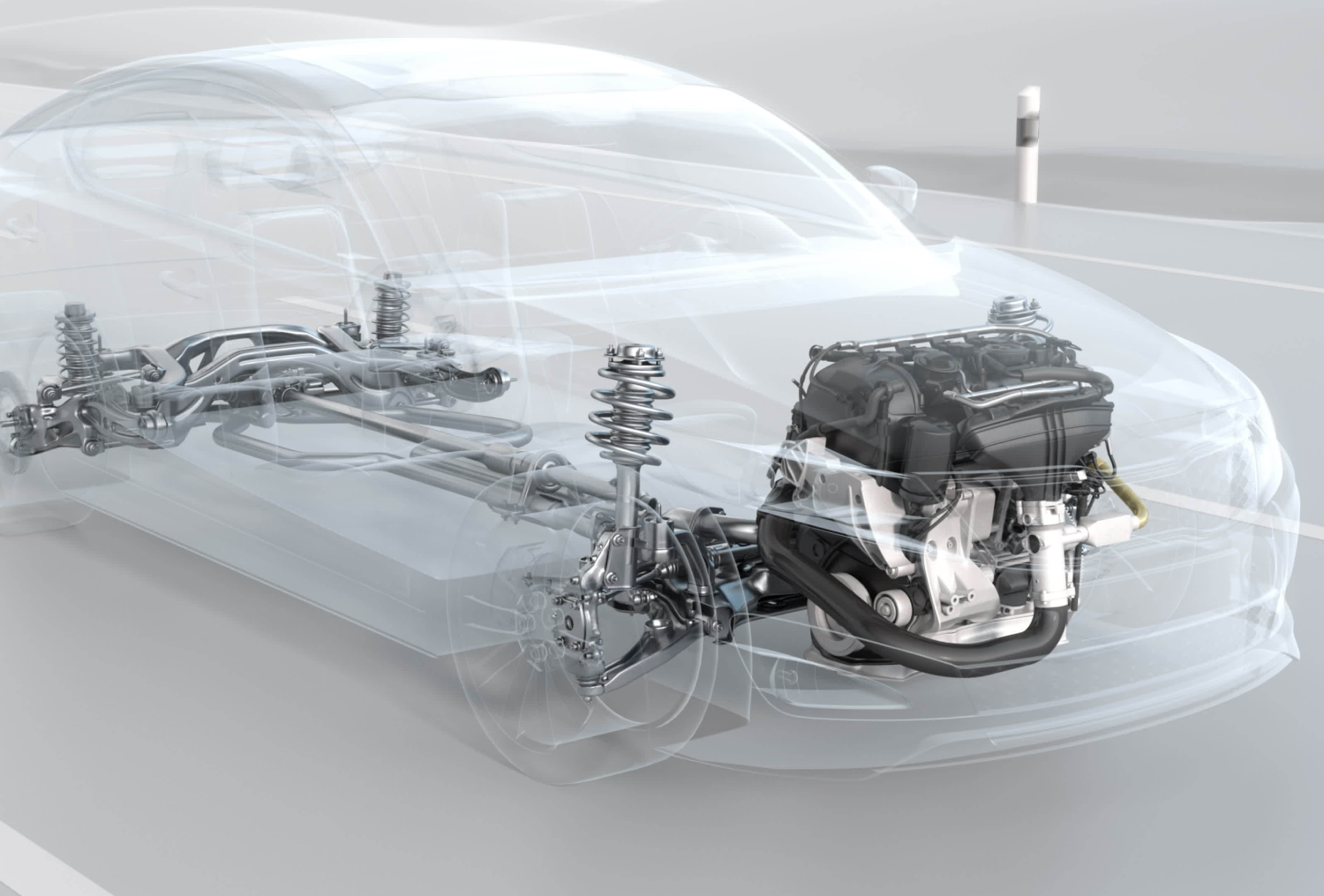

Conventional Powertrain

- Engine Performance

- Intake System

- EGR

- Exhaust (EAT)

- Turbocharger

- Oil Circuit

E - Powertrain

- Battery System

- Thermal/ SOC/ Aging/ Fast charging

- E-machine System

- Thermal

- Cooling Optimization

- Coupling with Electromagnetics

- Inverter Thermal management