Back

Back

Back

Electric Motor / EDU / Electric Machine Design Using Simulation

Motors in the EV are called as “electric engines”. Electric machine (E-machine) is an assembly of motor, transmission, cooling channels inside a housing. The design of E-machines is very critical from EMS, thermal, structural & NVH perspectives. E-machine contributes major share of mass in the E-powertrain assembly. Durability of Lightweight design becomes obviously an interesting topic in this regard.

Key Projects Expertise

- 2D EMS simulation of motor - Evaluation of performance criteria of motor & suggestion for motor selection.

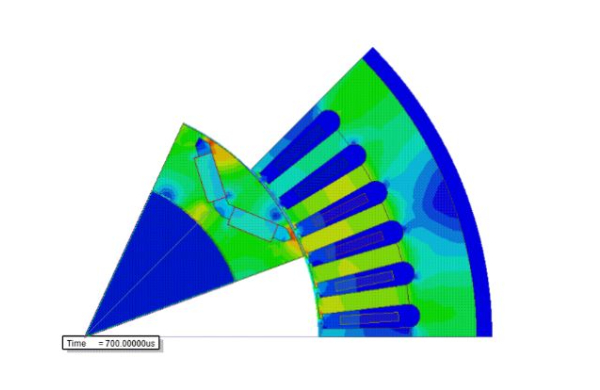

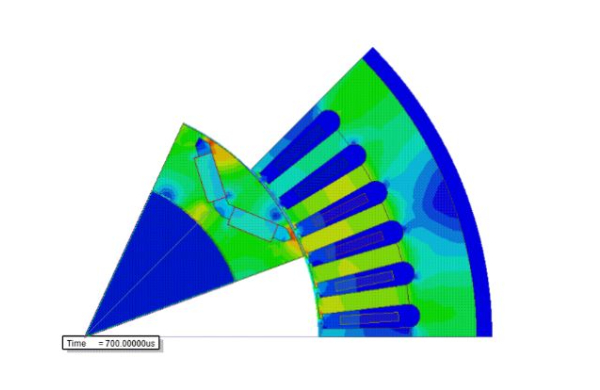

- Electro-magnetic-thermal co-simulations of motor - Prediction of losses like Ohmic, Stray & Eddy losses and mapping of heat sources for thermal analysis.

- Windage loss calculation- 3D CFD simulation for windage loss prediction.

- 3D CHT simulation- Evaluation and optimization of cooling performance.

- EMF coupled with cyclic vibration and acoustic motor analysis – determination of EMF, mapping of EMF as a frequency function, fatigue for cyclic vibration & determination of structure- borne noise, critical speed.

- 1D system level integration of electric motor – Evaluation of EM interaction of motor with the components & overall thermal performance of the motor.

- Optimization of rotor profile- determination of optimized rotor profile considering structural and EM requirements.

- Thermo- mechanical simulations of E-machines – determination of thermal stresses in the system for different duty cycles followed by high cycle fatigue (HCF).

- Oil sloshing simulation – determination of oil churning losses in the transmission system.

- Co-Simulation of integrated starter/generation system(ISG) – performance evaluation of motor and power electronic that comprises ISG module.