Battery Development Services

Empowering Innovation with Advanced Battery Solutions

As the world shifts its focus to sustainable and renewable energy solutions, batteries gain center stage. However, the move isn’t devoid of challenges, particularly when it comes to battery development. OEMs worldwide are confronting common challenges like quick charging strategy, range enhancement, thermal management, recyclability, durability, safety, and reliability. The need for advanced battery services therefore becomes evident and imminent!

This is where ESPL steps in. We specialize in cutting-edge battery development services to accelerate innovation in electric mobility, renewable energy, and industrial applications. Our profound commitment to sustainability, excellence, and performance drives our approach which involves providing end-to-end solutions to address every aspect of battery design, development, and optimization.

Our Offerings

1D Systems

- Battery Sizing

- Aging Prediction for real applications

- Performance Modeling

- Fresh Cell, Aged Cell

- Fast Charge strategy development

- Pack Design Analysis

- Thermal, Electrical, Mechanical

- Safety Analysis

- Thermal Runaway Propagation

- Co- Simulation with 3D CFD

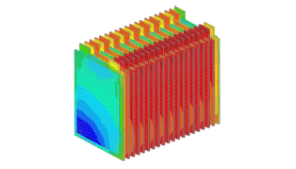

3D CFD

- Thermal Simulations

- Module/ Pack Level

- Coolant Flow Optimization

- Min. Pressure Drop

- Uniform Cooling

- Temperature Prediction

- Mapping of temperatures for thermal stress analysis

Structural Simulations

- Thermal Stress Analysis

- Drop/ Shock Test

- Crash Performance

- Strength/ Stiffness (Connectivity with Body)

- Random Vibration/ Durability

- Nail Penetration Test Simulation

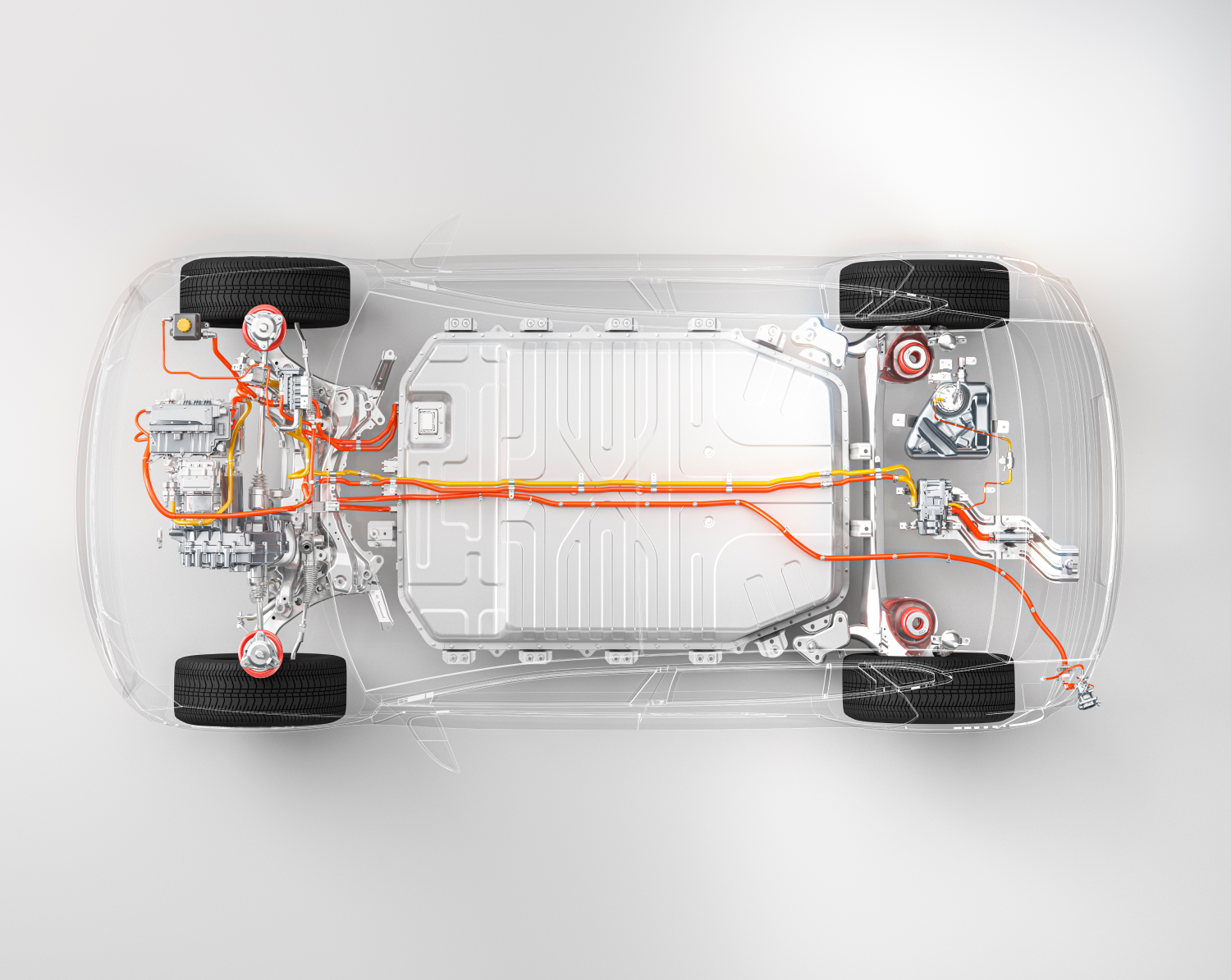

Integration with Vehicle Systems

Safety and performance are two crucial aspects in automobile manufacturing. Thus, one of the most significant aspects from the viewpoint of these factors include integrating a battery pack with the vehicle. However, doing so, involves addressing various key challenges that affect performance and safety.

- Thermal Management: Effective integration with the coolant system helps maintain optimal battery temperature. It prevents overheating and contributes to a consistent performance.

- Battery Controller and VCU Integration: In a vehicle, the battery management system (BMS) and Vehicle Control Unit (VCU) must interact seamlessly to ensure energy distribution, real-time monitoring, and performance optimization.

- Structural Integration: Additionally, integrating the battery pack securely into the vehicle’s frame contributes to the vehicle’s safety and stability. Besides, it helps balance strength, stiffness and weight to ensure optimal energy storage and performance.

Let’s Drive Innovations and Power the Future Together

At ESPL, we don’t merely build batteries but contribute to the future with our competent and next-gen energy solutions. We nurture a team that resonates with our client’s needs and dedicates itself to empowering the industry with reliable, and performant battery systems that meet and exceed industry standards.

We are prepared to deliver what it takes? Are you ready to embrace the future of energy? Contact us today to discuss your project and discover how ESPL can empower and expedite your journey to innovation.

Get in Touch